Menu

- Rotary Equipment

- INDUSTRIAL PUMPS

- Metals & Mining Equipment

- Drilling Equipment

- Industrial Valves

- Electrical Equipment and Accessories

- Catalysts & Chemicals To Petrochemical Industries

- Process Equipment

- Instrumentation

- Piping and Accessories

- Spare Parts

- Industrial Oil, Chemicals and Lubricants

- Sea Water Treatment Equipment (SWRO)

- Steel Products

Rotary equipment refers to mechanical devices that deliver kinetic energy to a process, enabling movement within various operations. These rotating machines are widely utilized across the process industry and typically involve components that transport solids, liquids, or gases through a combination of drivers, driven parts, and transmission systems.

At stepsco, such equipment is commonly found in steam and gas turbines. Steam turbines serve as the primary drivers by harnessing high-pressure steam to power rotary machines like forced or induced draft fans, pumps, and air compressors. In contrast, gas turbines may either use compressed air to operate generators or employ fluid couplings—such as scoop tubes—to drive the rotating machinery.

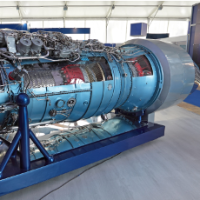

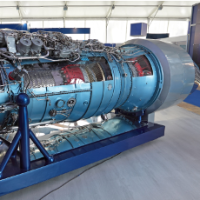

GAS TURBINE

A gas turbine is the soul of the power plants. Its main purpose is to generate electricity by heating a mixture of air and fuel, at high temperatures causing the turbine blades to spin. We remain supplier neutral and aim to select the finest gas turbines according to our clients’ requirements as well as minimising their costs.

STEAM TURBINE

Similarly, a steam turbine is equally important to the process industry. It transforms thermal energy to mechanical energy and the turbine can work with either constant or variable speeds depending on the type of application. They can be utilised as a mechanical drive for compressors and pumps, available in different sizes ranging from small to large

COMPRESSORS

A gas turbine is the soul of the power plants. Its main purpose is to generate electricity by heating a mixture of air and fuel, at high temperatures causing the turbine blades to spin. We remain supplier neutral and aim to select the finest gas turbines according to our clients’ requirements as well as minimising their costs.

Gear units & Couplings GEARBOXES

We offer a variety of gearboxes of different types, shapes and sizes such as worm, helical, planetary, and spur. Gear boxes are essentially used to alter speed, direction and the torque of the mechanical equipment. It is a vital piece of equipment; with just a small amount of rotational force, gear boxes are able to generate an even greater torque.

Industrial Fans

Fan is a device that circulates air. Fans have 3 major Duty include: suck air, blow air or circulate air.Fans are divided into the following categories according to the air flow direction relative to the fan axis:1-Axial fan 2-Centrifugal fan

Fans main accessories are the impeller and the Housing, which are the most important components. Include components whose fan proper functioning depends on their proper design and selection. One of the most important component is electric motor but other sources of power may be used, such as hydraulic motors, handcranks, and internal combustion engines, Shaft, bearing and power transfer system are the last component.

Industrial Blowers

The workhorses for industrial and domestic pumping applications are split casing pumps e.g. horizontally axially split casing, single stage, double suction pumps etc. These pumps are highly used in industries for handling water with impurities, petroleum refineries, air conditioning and refrigeration system and in the mining industry.

Hydraulic Turbines

There are two main types of hydropower turbines: reaction and impulse.

The type of hydropower turbine selected for a project is based on the height of standing water—referred to as “head”—and the flow, or volume of water over time, at the site. Other deciding factors include how deep the turbine must be set, turbine efficiency, and cost. Here are some of the most commonly used turbines in the United States today.

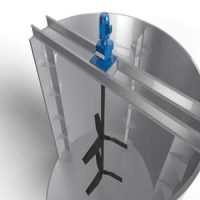

Mixers and Agitators & Stabilizer Mixer

Mixers and blenders are used throughout the process industries and include food – adhesive & sealant – green technologies – battery – ceramic & metal – chemical – coating – cosmetic & personal care products – pharmaceutical – plastic .

Extruders

An extruder is basically a screw pump; the screw(s) rotates in a tightly fitting stationery barrel. The semimoist feed or dry powder/grit is introduced into the extruder, usually at a constant rate of mass or volume employing a feeding mechanism. The material thus moves forward by the rotation of the flighted screw(s). Heat is usually supplied externally to the extruder barrel, and is partly produced by viscous dissipation of mechanical energy. The control of temperature is required at different sections of the extruder and at the die end. The material thus undergoes several unit operations like mixing, compression, shearing, and cooking inside the extruder, and is finally shaped in the die through which the material is forced to exit under pressure.

HEATING PUMP

The heating pump utilises promising techniques with multitude applications within the process industry. Such pumps are useful in conserving energy in industrial processes by recovering waste heat produced in plant and lift the temperature to a level high enough for reuse. Recoverable waste heat and process heat are found in industrial verticals like food processing, paper and pulp, refineries, and chemical industry etc. These types of pumps can also function reversibly as space coolers.

Screw Feeder & Screw Conveyors