Menu

- Rotary Equipment

- INDUSTRIAL PUMPS

- Metals & Mining Equipment

- Drilling Equipment

- Industrial Valves

- Electrical Equipment and Accessories

- Catalysts & Chemicals To Petrochemical Industries

- Process Equipment

- Instrumentation

- Piping and Accessories

- Spare Parts

- Industrial Oil, Chemicals and Lubricants

- Sea Water Treatment Equipment (SWRO)

- Steel Products

- Shell and Tube Heat Exchanger

- Centrifugal Machines

- Screw Conveyors

- Dryers

- Evaporators

- Evaporators

- Conveyors

- Furnaces/Heaters

- Dampers

- Dehydrators

- Cryogenic Equipment

- Bearings

- Hydraulic Hoese

- Autoclaves

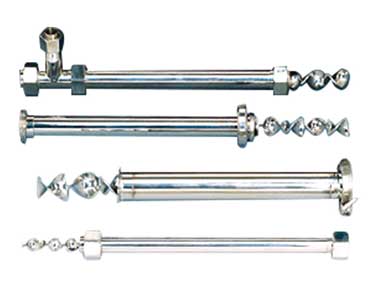

- Stabilizer Mixer

- Helical Static Mixer

Industrial processing equipment includes a broad spectrum of machinery and spare parts specifically designed to meet the demanding needs of various downstream industries. These systems are essential for facilitating processes and chemical reactions that cannot occur under standard environmental conditions due to limitations in temperature, pressure, or safety. Technological innovations in processing equipment—particularly in sectors such as oil & gas, mining, manufacturing, and construction—significantly enhance operational efficiency, production output, and overall plant profitability. We conduct thorough evaluations to gain precise insight into the specific equipment and accessory needs of each client, ensuring optimal performance and reliability.

AUTOCLAVES

Various scientific operations in laboratories require hygiene, disinfection and sterilisation of glassware and instruments. Very large in size and highly specialised autoclaves have been used for this specific task in industrial laboratories. Other than dairy operations, food processing units, wineries autoclaves also play major role in rubber industry for vulcanisation of rubber i.e. thermoplastic process, or making something mouldable by applying heat at specific temperature and pressurised environment.

FILTRATION

Manufacturers and industrial process facilities maintain their production levels in very high volumes. Pollutants always have the diverse effect on humans, machines, and the environment. Such factors have lead to a rising demand for extraction and filtration technology, which reliably protects equipment and employee health, and furthermore takes account of changing process parameters. Products that are easy to fit, robust enough to handle the environment and ones that can easily be replaced if needed are the requirement of the effective filtration system. An efficient filtration system and filters reduce the cost of raw materials used in industrial processes.

HEAT EXCHANGERS

Heat exchangers are one of the important components of air conditioning, cooling or heating systems in various industry verticals. Heat Exchangers play an important role to keep industrial machinery, chemicals, fluids, gas, and other substances within a safe operating temperature. Heat exchangers also have a wide range of industrial applications in oil and gas industry, power generation, chemical processing, space heating, refrigeration, petrochemical plants and refineries, and also in sewage treatment. Steam or heat exhaust released as a by-product of the process can also be captured or transferred for better utilisation with the help of heat exchangers which result in the increase in efficiency and enhance revenue.

DRYERS

Removal of water vapor and condensation from main lines of pneumatic systems is best performed through use of membrane (wicking), desiccant (adsorption) and refrigerated (refrigerant) Air Dryers. The varying outlet pressure dew points of compressed air dryers mitigate humidity in the air line, which in turn, will help avoid corrosion within the system and prolong pneumatic component lifespans. The lower the dew point temperature, the drier the air downstream will be.